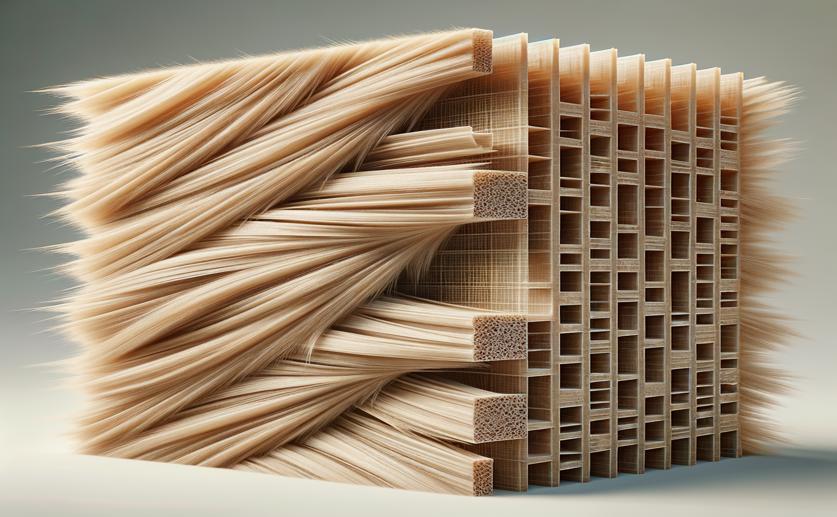

Creating Lightweight, Strong Panels with Banana Fibers and Glass-Clay Core

Jenn Hoskins

8th May, 2024

Image Source: Natural Science News, 2024

Key Findings

- Researchers at Durban University of Technology developed a new lightweight, strong composite material

- The composite includes hollow glass microspheres, nanoclay, and banana fiber, improving strength and buoyancy

- This material could benefit industries needing durable yet light structures, like aerospace and marine

References

Main Study

1) Development of epoxy-based sandwich composite panel with hollow glass microspheres/clay hybrid core and banana fiber facesheet for structural applications.

Published 15th May, 2024 (future Journal edition)

https://doi.org/10.1016/j.heliyon.2024.e30428

Related Studies

2) Analysis of Particle Variation Effect on Flexural Properties of Hollow Glass Microsphere Filled Epoxy Matrix Syntactic Foam Composites.

3) Impact of Hybrid Fillers on the Properties of High Density Polyethylene Based Composites.

6th May, 2024 | Jenn Hoskins

6th May, 2024 | Jenn Hoskins