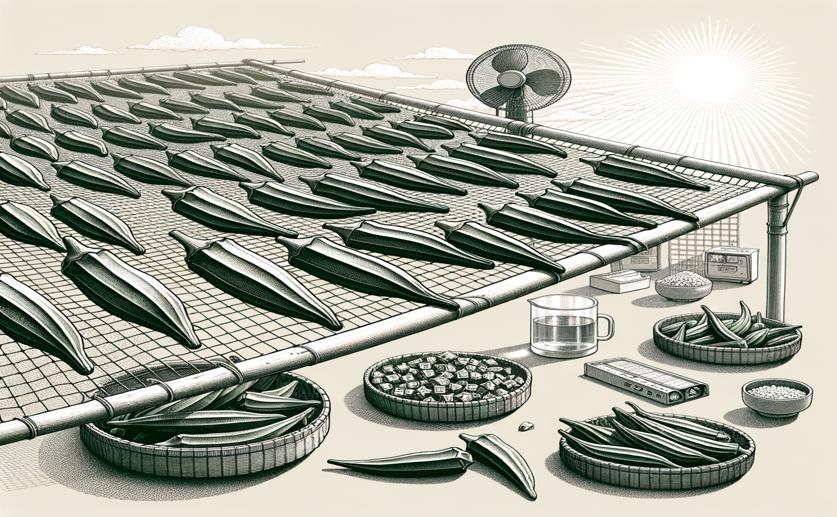

Exploring Efficient Solar Drying Methods for Okra

Jenn Hoskins

6th May, 2024

Image Source: Natural Science News, 2024

Key Findings

- Researchers developed a solar dryer that efficiently dries okra using renewable energy

- The best pre-treatment for okra was hot water at 80°C for 5 minutes, balancing drying rate and quality

- The solar dryer is cost-effective with a payback period of 1.27 years and can reduce CO2 emissions

AgricultureEnvironmentSustainability

References

Main Study

1) Investigation of thermal performance, drying characteristics and environomical analysis: direct flow evacuated tube solar drying of okra.

Published 3rd May, 2024

https://doi.org/10.1007/s11356-024-33340-8

Related Studies

2) Sustainable food drying technologies based on renewable energy sources.

3) Changes in total phenolic content and color of bottle gourd (Lagenaria siceraria) juice upon conventional and ohmic blanching.

4) Legume seed system performance in sub-Saharan Africa: barriers, opportunities, and scaling options. A review.

15th March, 2024 | Greg Howard

15th March, 2024 | Greg Howard