Creating Textured Apple-Based Ingredients with Sesame Waste

Jenn Hoskins

27th April, 2024

Image Source: Natural Science News, 2024

Key Findings

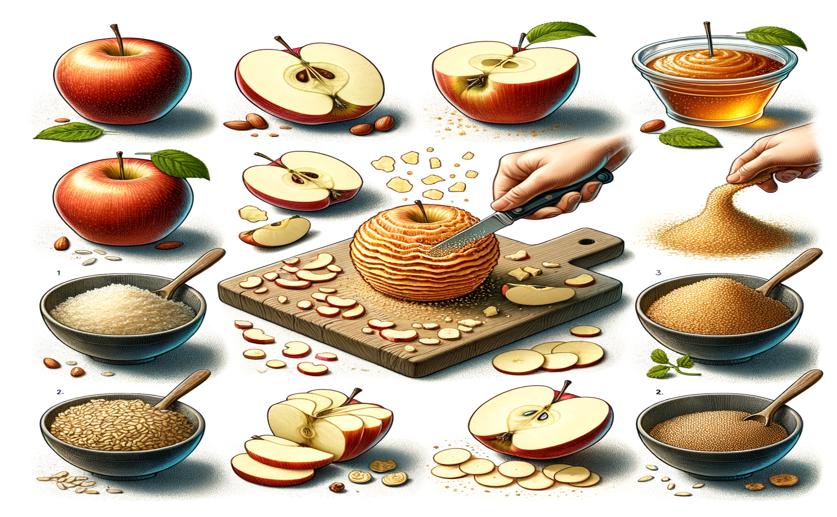

- In Iran, a study optimized turning apple and sesame by-products into nutritious food ingredients

- The best conditions for processing were 176 rpm screw speed, 18% moisture, and a 75:25 apple to sesame mix

- The resulting food ingredients can improve the nutrition of foods like porridge and cookies

References

Main Study

1) Fabrication of textured functional ingredient based on apple: Sesame by-product.

Published 30th April, 2024 (future Journal edition)

https://doi.org/10.1016/j.heliyon.2024.e28841

Related Studies

2) Production of high fiber ready-to-eat expanded snack from barley flour and carrot pomace using extrusion cooking technology.

3) Mechanical Properties of Biocomposites Using Polypropylene and Sesame Oil Cake.

4) Utilization of Food Processing By-products as Dietary, Functional, and Novel Fiber: A Review.

21st January, 2024 | Jenn Hoskins

21st January, 2024 | Jenn Hoskins