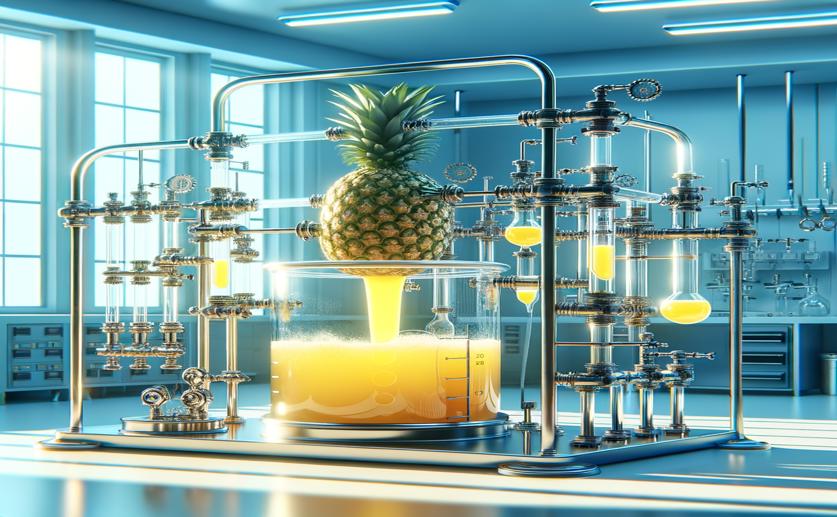

Improving Continuous Ohmic Heating with Pineapple Juice Properties

Jim Crocker

4th April, 2024

Image Source: Natural Science News, 2024

Key Findings

- Researchers at Tezpur University found that continuous ohmic heating (COH) can effectively pasteurize pineapple juice

- The efficiency of COH is influenced by the juice's sugar-to-acid ratio and the strength of the electric field applied

- An artificial neural network model accurately predicted the heating rate, optimizing the pasteurization process

References

Main Study

1) Influence of °Brix/Acid, and flow rate of pineapple juice and electric field strength on the performance of continuous ohmic heating system.

Published 2nd April, 2024

https://doi.org/10.1007/s13197-024-05961-x

Related Studies

2) Effect of continuous ohmic heating to inactivate Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice and tomato juice.

3) Effect of dielectric barrier discharge nonthermal plasma treatment on physicochemical, nutritional, and phytochemical quality attributes of pineapple [Ananas comosus (L.)] juice.

9th January, 2024 | David Palenski

9th January, 2024 | David Palenski